In the PCB industry the term ‘Burn-in Board’ is very common but if you’re just getting into the industry you might be scratching your head a little as to what one is!

We’ve been making burn-in boards for Semiconductor companies all around the world since 1994 -it’s like second nature to us. So, we thought we’d explain them for you in a little more detail….

Burn-in Process

First of all, ‘burn-in’ is a process where semiconductor components are stress tested in order to detect any early failures due defects in design, materials, process or manufacturing .

The tests that are run will try to trigger possible failures that could happen in the real world and improvements can be made if necessary. Very often the semiconductor components are pushed beyond what they will have to go through in reality to allow for additional headroom. This ensures the manufacturer can be confident they have a robust end product.

The ‘Bathtub Curve’

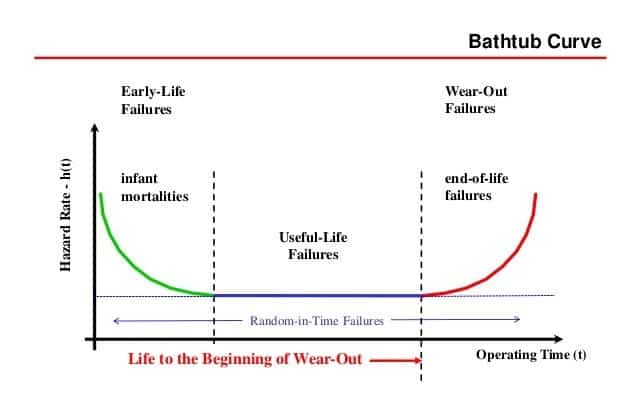

The typical lifespan and early failure rates of semiconductors can best be illustrated by the ‘Bathtub Curve’ as detailed in the diagram above. The nature of semiconductors is that many failures occur during the early stages of operational life (infant mortalities). By elevating the temperature during test the failure mechanisms are accelerated to eliminate any early device failures. The component will then be operating in the useful life phase. This is the Burn-in Process.

The Boards

A burn-in board is a printed circuit board that is used in the burn-in process.

The components added to the board are stressed using extreme heat to highlight any failures. Once the stress tests have been completed engineers will analyse the results to make sure everything is working within the correct parameters.

During the burn-in process extreme temperatures often ranging from 125°C – 250°C or even 300°C are applied so the materials used need to be extremely durable. Generally speaking we use IS410 for applications up to 155°C and polyimide for applications up to 250°C. For temperatures over 250°C a higher grade of polyimide is used. We also use high temperature lead free solders and stainless-steel board fixtures.

The boards that Abrel produce can be tailored for all system types and a wide variety testing conditions including HAST, LTOL, *85/85 and HTOL.

Our design engineers use Seetrax Ranger CAD workstations, which are optimised for efficient burn-in board design. Abrel completes over 200 Burn-in board design projects per year.

Burn-in Design Innovation

One of the challenges facing burn-in board manufactures is keeping pace with a rapidly moving industry. At Abrel Product we constantly work on our designs and focus on innovation to meet the needs of our clients.

The burn-in board design is pretty similar to standard PCB guidelines, but additional elements need to be considered. Having a reliable board-in board or IC test socket is extremely important so they don’t fail during test phase. This is major part of our focus during the design phase.

Also, it is very important that both active and passive components and materials used on the board need to comply with the temperature requirements in the design brief.

Learn More

If you would like to find out more about our burn-in boards or burn-in systems please contact a member of our team.